What are side guide rollers?

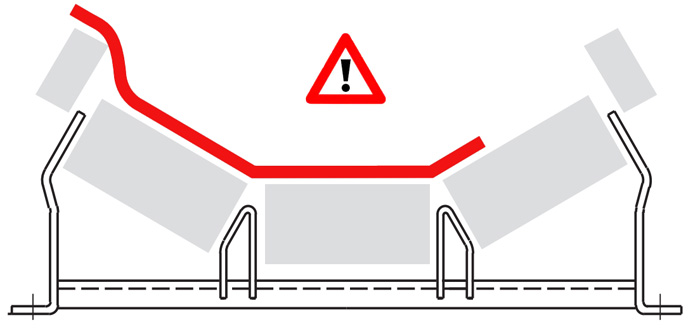

Guide rollers ensure proper alignment and tracking of conveyor belts, reducing maintenance issues and extending belt life.

They are placed at critical points along the conveyor path to keep belts from running off the pulleys and preventing drift.

This alignment minimizes wear on the belt edges and prevents material spillage.

What materials are guide rollers made of?

| Material | Abrasive Resistance | Fatigue Resistance | Sustainability | Thermal Conductivity | Toughness | Corrosion Resistance |

|---|---|---|---|---|---|---|

| Mild Steel | ★★★★ | ★★★★ | ★★★★★ | ★★★★ | ★★★★ | ★★ |

| Polyurethane | ★★★ | ★★★ | ★ | ★ | ★★★★ | ★★★★ |

| Rubber | ★★★ | ★★ | ★ | ★ | ★★★★ | ★★★ |

| Plastics | ★★ | ★★ | ★★ | ★ | ★★★ | ★★★★ |

Sources

Abrasion Resistance:

https://www.steelwarehouse.com/abrasion-resistant-steel/

https://www.nextgentest.com/blog/din-abrasion-tester-and-standards-of-rubber-testing/

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10144973/

https://www.elastocon.com/learn-more/about-testing/determination-of-abrasive-wear-resistance

https://erez-therm.com/abrasion-resistance/

https://coatings.specialchem.com/coatings-properties/abrasion-resistance

Fatigue Resistance:

https://step-lab.com/astm/astm-d7791/

https://www.testresources.net/applications/standards/astm/astm-d7791-uniaxial-fatigue-properties-of-plastics

https://www.smithers.com/services/testing/standard/astm/astm-d4482

https://intapi.sciendo.com/pdf/10.1515/fas-2014-0006

https://en.wikipedia.org/wiki/Fatigue_limit

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9369594/

Sustainability:

https://sections.arcelormittal.com/repository2/Sections/6_58_EPD%20Structural%20Steel%20sections%20and%20merchant%20bars.pdf

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2873020/

https://citeseerx.ist.psu.edu/document?doi=457d518e5e15efb460de5a3c44384a8b869a4932&repid=rep1&type=pdf

https://pcr-epd.s3.us-east-2.amazonaws.com/470.EPD_for__Rebar_FINAL_20191212.pdf

https://www.mdpi.com/2076-3417/14/2/737

https://www.iso.org/plasticpollution

https://www.astm.org/products-services/standards-and-publications/standards/plastics-standards.html

https://www.behr.com/binaries/content/assets/behrpro/pdf/epd/116.1_behr-alkyd-enamel-epd.pdf

Thermal Conductivity:

https://thermtest.com/testing-services/thermal-conductivity

https://www.tainstruments.com/pdf/literature/Accurate%20Simultaneous%20Measurements%20of%20Thermal%20Conductivity%20and%20Specific%20Heat.pdf

https://en.wikipedia.org/wiki/List_of_thermal_conductivities

https://www.engineersedge.com/properties_of_metals.htm

https://australianmodernbuildingalliance.org.au/images/amba/resources/Physical_properties_of_polyurethane_insulation.pdf

https://www.govinfo.gov/content/pkg/GOVPUB-C13-9d3193e93202905da6c546702b1a9d73/pdf/GOVPUB-C13-9d3193e93202905da6c546702b1a9d73.pdf

https://www.osti.gov/biblio/840826

https://www.astm.org/d5930-17.html

https://iopscience.iop.org/article/10.1088/1742-6596/2069/1/012090/pdf

Toughness:

https://tspace.library.utoronto.ca/bitstream/1807/13366/1/MQ45596.pdf

https://www.instron.com/-/media/literature-library/products/2021/03/impact-handbook.pdf?la=en

https://www.govinfo.gov/content/pkg/GOVPUB-C13-9d3193e93202905da6c546702b1a9d73/pdf/GOVPUB-C13-9d3193e93202905da6c546702b1a9d73.pdf

https://www.sunray-inc.com/technical-data/

https://www.osti.gov/biblio/840826

https://omnexus.specialchem.com/polymer-property/toughness

https://www.nextgentest.com/blog/the-process-of-plastic-impact-testing-and-impact-sample-preparation-for-plastics/

Corrosion Resistance:

https://www.plymouth.com/resources/corrosion-testing-of-metals-is-it-needed/

https://tft-pneumatic.com/blog/astm-corrosion-tests-and-standards/

https://www.govinfo.gov/content/pkg/GOVPUB-C13-9d3193e93202905da6c546702b1a9d73/pdf/GOVPUB-C13-9d3193e93202905da6c546702b1a9d73.pdf

https://www.journal-dogorangsang.in/no_1_sept-dec_20/112.pdf

https://www.academia.edu/82610815/Analysis_of_the_Effect_of_Abrasive_Material_and_Polyurethane_Coating_Thickness_Variations_on_ASTM_A36_Steel_Towards_Corrosion_Rate_in_Sea_Water_Environment

https://www.astm.org/products-services/standards-and-publications/standards/plastics-standards.html

https://blog.ansi.org/2020/04/iso-12944-corrosion-protection-steel-paint/

https://www.smithers.com/industries/materials/polymer/physical-testing/environmental-resistance-testing/corrosion-testing

Abrasive Resistance: The ability to withstand wear when in contact with abrasive materials, such as gravel or sand.

Fatigue Resistance: The ability to endure repeated stress cycles without failure.

Sustainability: The ability to be efficiently recycled and reused at the end of their service life.

Thermal Conductivity: The ability to conduct heat generated from friction and continuous operation.

Toughness (impact): The ability to absorb energy and withstand shock and impact without cracking.

Corrosive Resistance: The ability to resist damage from corrosive environments, such as exposure to chemicals or moisture.

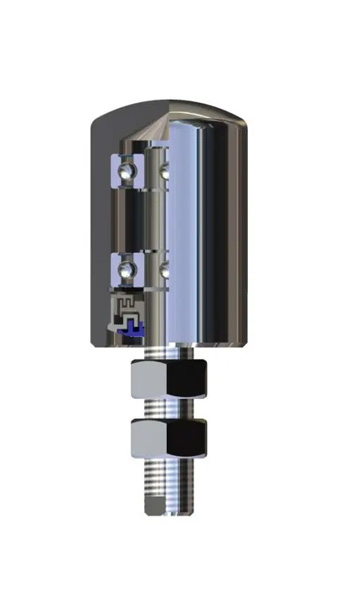

Steel

Pros:

Cons:

List of Steel Guide Roller Manufacturers

| Manufacturer | Image | HQ | Availability |

|---|---|---|---|

| rulmeca.com |  | Italy | Global |

| proguideroller.com |  | Canada | Canada, USA, South America Order Online |

| krumscheid.de |  | Germany | |

| kuepper.eu |  | Germany |

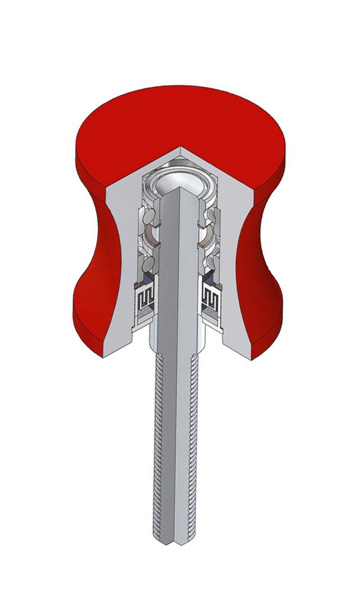

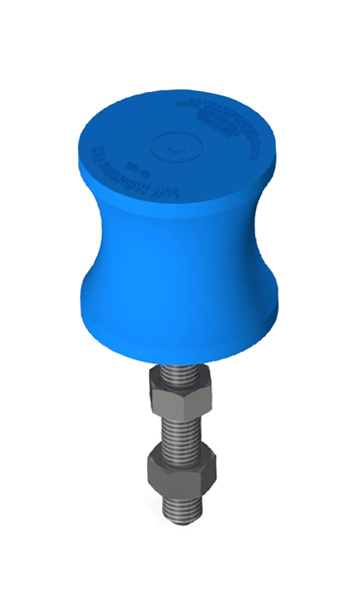

Polyurethane

Pros:

Cons:

List of Polyurethane Guide Roller Manufacturers

| Manufacturer | Image | HQ | Availability |

|---|---|---|---|

| ppi-global.com |  | USA | Canada, USA, South America |

| kinder.com.au |  | Australia | Global |

| luffindustries.com |  | Canada | Canada, USA |

| americaneaglemanufacturing.com |  | USA |

Rubber

Pros:

Cons:

List of Rubber Guide Roller Manufacturers

| Manufacturer | Image | HQ | Availability |

|---|---|---|---|

| everpads.com |  | Taiwan |

Plastic

Pros:

Cons:

List of Plastic Guide Roller Manufacturers

| Manufacturer | Image | HQ | Availability |

|---|---|---|---|

| kuepper.eu |  | Germany |

Frequently asked questions

Why are guide rollers essential for alignment?

Guide rollers are strategically positioned along the conveyor at key points including turns, transitions, and loading zones.

Their placement prevents the belt from rubbing against the conveyor frame, thereby avoiding edge damage.

This setup improves the overall conveyor efficiency and safety by reducing spillage and uneven wear.

How do you measure guide rollers to ensure the belt is properly aligned?

Roller Diameter: Ensure the roller’s outer diameter aligns with the conveyor’s specifications to provide adequate contact with the belt edges.

Face Length: Measure the contact surface length of the roller, which influences the steering force applied to the belt.

Mounting Bracket Dimensions: Check the size and bolt hole spacing of the brackets to ensure they fit securely to the conveyor frame.

Clearance from Belt: Aim for approximately a 1-inch gap between the roller and the belt when centered without interference.