Different materials exhibit distinct characteristics that can significantly impact conveyor performance and efficiency. Understanding these material characteristics is essential for ensuring smooth operations, preventing costly downtime, and optimizing conveyor systems.

Select a Material

Result

| Material | |

|---|---|

| Abrasiveness | |

| Suggested Grade | |

| Bulk Density (t/m³) | |

| Bulk Density (lb/ft²) | |

| Angle of Surcharge (degrees) | |

| Max. Conveyor Slope (degrees) |

FAQ

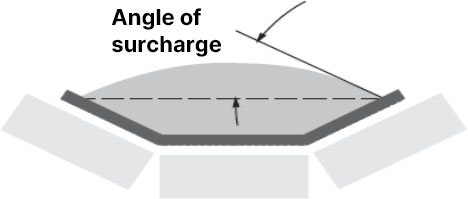

The angle of surcharge refers to the natural slope or angle that a material forms when it is stacked without any external influence. It is the angle at which the material tends to rest or settle due to its physical properties, such as cohesion and friction. This angle is crucial to consider when designing a belt conveyor system as it affects material flow, stability, and the required conveyor inclination.

"Suggested grade" is a term used to classify materials based on their suitability for transportation on belt conveyors. It provides guidance on the material's flowability, abrasiveness, and other characteristics relevant to conveyor performance. The suggested grade helps in selecting the appropriate conveyor components and determining factors such as chute lining, belt specifications, and operational considerations.

Bulk density refers to the mass of a material per unit volume, typically expressed in units such as tons per cubic meter (t/m³) or pounds per square foot (lb/ft²). It provides information about the material's compactness, weight, and load-bearing capacity. Bulk density is essential for calculating conveyor capacity, determining belt tension requirements, and ensuring efficient material flow and handling.