Side Guide Roller for Conveyor Belt (Steel)

$149.00 – $269.00 USD

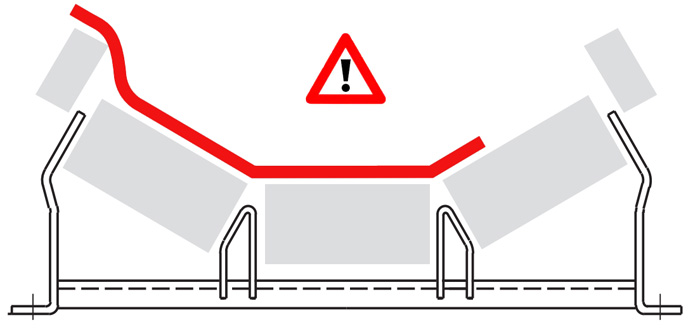

Our steel guide rollers keep the conveyor belt in alignment, secure the belt edge and encapsulate the full movement of the belt.

| Ships from Sault Ste. Marie, MI |

| Covered by a 2 year warranty |

| Sign in for fast checkout |

| 4 kg / 8.8 lbs |

Minimize conveyor downtime with self-aligning steel guide rollers

Keep the belt aligned and on track, preventing it from drifting off course and causing damage to the conveyor system.

Contents:

Trusted by:

Benefits

Keep the conveyor belt in alignment

Prevent your conveyor belt from moving off course, causing material spillage, safety hazards, and unnecessary belt damage.

Outlasts rubber, UHMW, nylons, plastics, and polyurethane

Cheaper side guide rollers last months compared to a quality steel guide roller which can last years.

Secure the belt edge

Maintain a safe and reliable conveyor system to optimize your production processes and minimize downtime.

Made for surface & underground mining, cement, aggregate, and corrosive rock salts

Trusted by international mining companies to operate in the harshest environments and applications.

Applications

Mining and mineral processing

Aggregate and sand production

Agriculture – grains, fertilizers

Forestry – lumber, pulp and paper mills

Installation

- Near the tail and drive pulleys

- At loading and unloading zones where material is fed onto or discharged from the belt

- Before and after transition points or direction changes in the conveyor path

- In long straight sections and inclined/declined sections of the conveyor

- Areas of high belt tension

- On the carry (top) side and return (bottom) side of long conveyors over 200 ft long or with high speeds, installed every 100 ft

- Where the conveyor experiences pronounced belt run-off tendency and considerable transverse forces (e.g. side loading, diverter bars, multiple redirections in belt path)

- Behind the loading point if there is a long slack side

- Where the same part of the belt always tends to run off regardless of its position on the conveyor (indicating potential belt damage or uneven wear)

Options

Heat Treatment

We highly recommend heat-treated rollers for heavy-duty applications and maximum service life, and our soft rollers for lighter applications.

| Feature | Heat Treated (Hard) | Soft Rollers |

|---|---|---|

| Durability | Very High | High |

| Wear Resistance | Superior | Good |

| Service Life | Longer | Standard |

| Cost | $229 | $149 |

| Dust Covers | Optional (+$10) | Optional (+$10) |

| Best For | Abrasive/Heavy-Duty | Light/Medium-Duty |

Dust Cover

Mechanical dust covers prevent debris and dust from entering the inner bearing core which could lead to damaging the leading edge of the belt – we highly recommend them.

Note for installation: Dust covers are typically only needed when the guide roller is mounted above the belt (steel spindle / shaft pointing upwards), as gravity may allow contaminants to enter the bearing core.

Frequently asked questions

What are side guide rollers?

Guide rollers ensure proper alignment and tracking of conveyor belts, reducing maintenance issues and extending belt life.

They are placed at critical points along the conveyor path, such as near turns and transitions, to keep the belt centered and prevent drift.

This alignment minimizes wear on the belt edges and prevents material spillage, enhancing operational efficiency.

Guide rollers are made from durable materials like steel, designed to withstand constant friction and pressure from the moving belt.

Why are guide rollers essential for alignment?

Guide rollers are strategically positioned along the conveyor at key points including turns, transitions, and loading zones.

Their placement prevents the belt from rubbing against the conveyor frame, thereby avoiding edge damage.

This setup improves the overall conveyor efficiency and safety by reducing spillage and uneven wear.

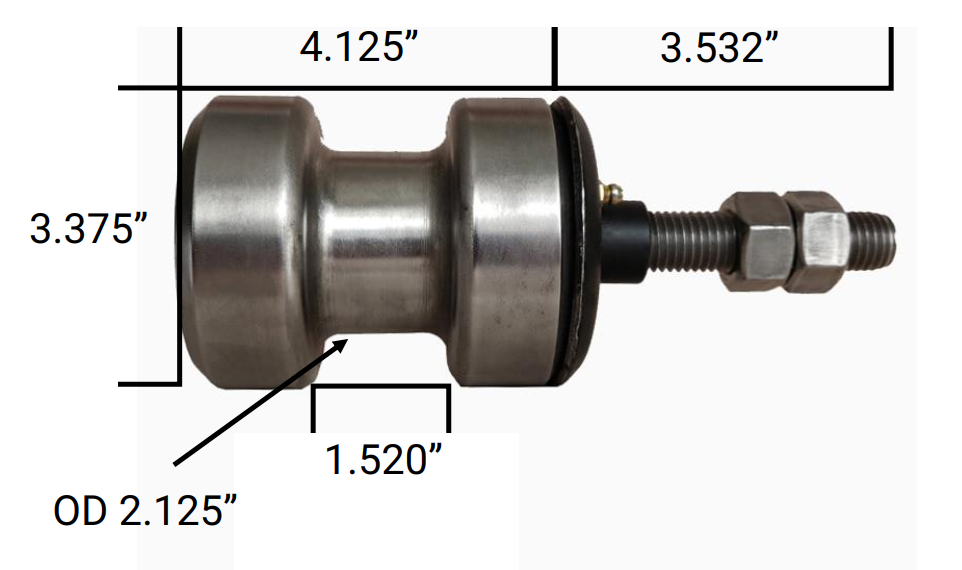

How do you measure guide rollers to ensure the belt is properly aligned?

Roller Diameter: Ensure the roller’s outer diameter aligns with the conveyor’s specifications to provide adequate contact with the belt edges.

Face Length: Measure the contact surface length of the roller, which influences the steering force applied to the belt.

Mounting Bracket Dimensions: Check the size and bolt hole spacing of the brackets to ensure they fit securely to the conveyor frame.

Clearance from Belt: Aim for approximately a 1-inch gap between the roller and the belt when centered without interference.

| Size | Standard (4 1⁄8"), Long (12") |

|---|---|

| Treatment | No Heat Treatment, Heat Treatment |

| Dust Cover | No Dust Cover, Dust Cover |

3 reviews for Side Guide Roller for Conveyor Belt (Steel)

We are using these on our reversing belts and had such good luck with the first 6 we brought in back in July, they asked me to order 8 more.

Response from PROGUIDE

Thank you David for your feedback and the pictures of the guide roller in action!

We are using both the regular guide rollers for self-aligning rollers. We just currently bought the 6” diameter rollers as well. They are great products!

Ontario Trap Rock has been using hardened guide rollers for 4 years and have had great success with them. They more than double the life of any you can buy from OEM suppliers. With being able to change out the common size bearings, if needed, their up-time is 100%. Greasable dust covers make them last in the most harsh conditions. I highly recommend them with any conveyor in the rack or return side applications.