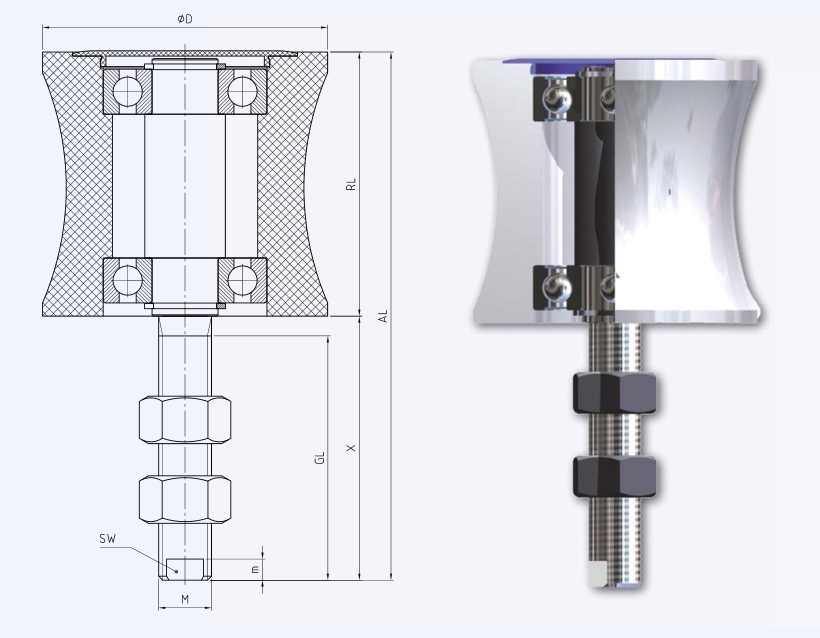

1. Plastic

Plastic guide rollers have several benefits over their metal counterparts.

For one, they are much lighter, which makes them easier to handle and install.

This can be especially important in applications where the rollers need to be moved frequently or installed in tight spaces.

Plastic guide rollers are also resistant to corrosion, so they can be used in damp or wet environments without the risk of rust or other forms of corrosion.

Additionally, they are often less expensive than metal rollers, which makes them a cost-effective option for many applications.

Manufacturer: Küpper, Canada

Link to their Brochure: https://www.kuepper.eu/images/PDF/Bulk_Material_Cataloque_2016-small.pdf

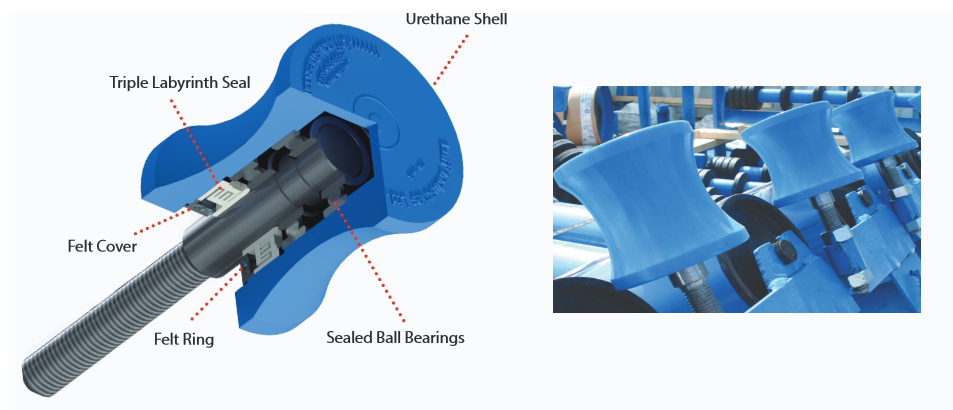

2. Urethane

Urethane guide rollers have several benefits over other types of rollers. For one, they are very durable and resistant to wear and tear, which makes them long-lasting and reliable.

They are also able to withstand high temperatures and harsh environments, making them suitable for use in a wide range of applications.

Urethane rollers are also very versatile and can be customized to meet specific needs or requirements.

Additionally, they are often quieter and smoother-rolling than other types of rollers, which can be important in applications where noise or vibration is a concern.

Manufacturer: Luff Industries, Canada

Luff Industries specializes in the design and manufacturing of conveyor components and accessories. The company was founded in 1978 in Alberta, Canada.

Visit luffindustries.com

Manufacturer: Superior Industries, United States

Superior Industries, founded in 1972, has evolved from a local repair and fabrication business to a global leader in bulk material handling equipment, offering innovative solutions and serving industries worldwide.

Visit superior-ind.com

Manufacturer: Kinder, Australia

Kinder Australia was established in 1985 by Neil Kinder, who recognized the need for high-quality conveyor components in the Australian market. Initially starting as a small operation, Kinder Australia quickly gained a reputation for providing innovative and reliable products.

Link to their product page: https://kinder.com.au/products/k-side-guide-rollers/

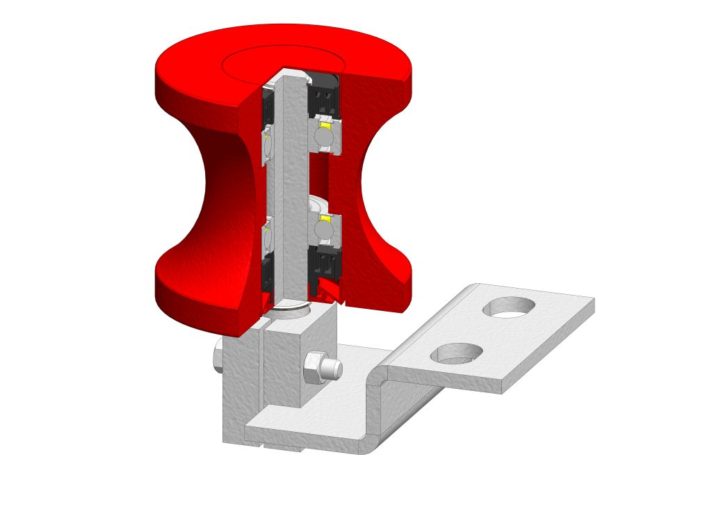

3. Hardened Steel

Hardened steel guide rollers have several benefits over other types of rollers.

For one, they are extremely durable and resistant to wear and tear, which makes them long-lasting and reliable.

The hardening process used to create these rollers also makes them more resistant to bending, twisting, and other forms of deformation, which can be important in applications where the rollers are subject to heavy loads or impacts.

Hardened steel rollers are also able to withstand high temperatures and harsh environments, making them suitable for use in a wide range of applications.

Additionally, they are often more rugged and heavy-duty than other types of rollers, which can be important in applications that require extra strength or support.

Manufacturer: ProGuide Roller Co., Canada

In 2009, a local aggregate supplier presented us with a challenge. The durability of their conveyor belts was being compromised by the strain caused by their tough aggregate material. Seeking a solution, we engineered a patented heavy-duty guide roller crafted from high-quality, case-hardened steel.

Link to our product page: https://proguideroller.com/product/guide-roller-for-belt-conveyor-steel/