Cone crushers combine advanced design, automation, and safety features with technological enhancements for superior performance.

Models vary from durable and efficient to flexible and safe, catering to different operational needs.

Highlighting unique attributes aimed at optimizing performance and efficiency, they are pivotal in aggregate and mining industries.

Here is a list of the highest capacity, versatility, and efficiency, followed by 6 of the best cone crusher manufacturers on the market:

Capacity, Versatility, and Efficiency

Largest Capacity

- MP2500 – 7,166 mtph – Metso

- Raptor 2500 – 3,502 mtph – FLSmidth

- MP1250 – 3,025 mtph – Metso

- MP1000 – 2,420 mtph – Metso

- TG1020 – 2,300 mtph – Terex

Most Versatile

- CH430 – Sandvik

- TC84XR – Weir

- CH420 – Sandvik

- CH870i – Sandvik

- TC51 – Weir

Based on capacity range vs. CSS range

Most Energy Efficient

- TC84XR – Weir

- TGS420 – Terex

- TG1020 – Terex

- CS660 – Sandvik

- HP900 – Metso

Based on power consumption vs. capacity

FLSmidth

FLSmidth’s Raptor® Cone Crushers incorporate several technical features designed for efficiency, durability, and ease of maintenance in mining and aggregate applications:

- Mainframe Inspection Ports and Cartridge Countershaft Boxes: These features facilitate easier access for inspection, maintenance, and replacement of key components.

- Diverse Product Line: The Raptor Cone Crushers come in a wide range of sizes and configurations to meet various operational requirements.

- Inverted Tramp Release Cylinders: This design ensures the cylinder rod is protected and faces downwards, enhancing the durability of the system.

- Digital Enhancements: Some models are equipped with digital capabilities for improved operational control and maintenance.

- Robust Design: The Raptor® XL900, for example, features a 70-inch (1.8 m) head diameter and an integral countershaft built into the four-arm mainframe for increased strength and durability.

- Direct Client Input and Feedback: The design and features of the Raptor Cone Crushers are influenced by direct feedback from users, ensuring their reliability and effectiveness in real-world applications.

- Versatility: These crushers are designed to be easily mounted and transportable on a portable cone/screen chassis, offering flexibility in various operational settings.

- Matched Pinion and Gears: This allows for the replacement of either the gear or pinion without needing to change the mating piece, simplifying maintenance and reducing downtime.

These features collectively make the Raptor® Cone Crushers suitable for demanding mining and aggregate applications, focusing on performance, durability, and ease of maintenance.

Sources

https://www.flsmidth.com/-/media/brochures/brochures-products/crushing-and-sizing/2021/raptor-cone-crusher_brochure.pdf

https://www.flsmidth.com/en-gb/products/crushing-and-sizing/raptor-cone-crusher-aggregates

https://www.flsmidth.com/-/media/brochures/brochures-products/crushing-and-sizing/2023/raptor-cone-crushers-with-advanced-technology-for-aggregates_brochure.pdf

https://www.flsmidth.com/en-gb/discover/mining-2021/raptor-cone-crusher-gamechanger-production-and-operations

FLSmidth Table

Metric

| Model | Weight (kg) | Power (kWh) | Max Feed (mm) | Min Capacity (mtph) | Max Capacity (mtph) | Min CSS (mm) | Max CSS (mm) |

|---|---|---|---|---|---|---|---|

| Raptor 250 | 8,917 | 190 | 235 | 120 | 310 | 10 | 45 |

| Raptor 350 | 16,089 | 260 | 240 | 140 | 520 | 10 | 45 |

| Raptor 450 | 24,470 | 340 | 335 | 160 | 640 | 10 | 45 |

| Raptor 500 | 51,113 | 370 | 330 | 195 | 730 | 10 | 45 |

| Raptor 650 | 65,522 | 450 | 380 | 220 | 800 | 10 | 45 |

| Raptor 900 | 71,648 | 670 | 345 | 272 | 1,243 | 10 | 45 |

| Raptor 1100 | 151,848 | 820 | 415 | 549 | 1,971 | 13 | 45 |

| Raptor 1300 | 151,955 | 970 | 415 | 685 | 1,955 | 13 | 45 |

| Raptor 2500 | 401,089 | 1,860 | 450 | 1,030 | 3,502 | 13 | 45 |

Imperial

| Model | Weight (lbs) | Power (hp) | Max Feed (in) | Min Capacity (stph) | Max Capacity (stph) | Min CSS (in) | Max CSS (in) |

|---|---|---|---|---|---|---|---|

| Raptor 250 | 19,659 | 255 | 9.25 | 132 | 342 | 0.39 | 1.77 |

| Raptor 350 | 35,470 | 349 | 9.45 | 154 | 573 | 0.39 | 1.77 |

| Raptor 450 | 53,947 | 456 | 13.19 | 176 | 705 | 0.39 | 1.77 |

| Raptor 500 | 112,685 | 496 | 12.99 | 215 | 805 | 0.39 | 1.77 |

| Raptor 650 | 144,451 | 603 | 14.96 | 243 | 882 | 0.39 | 1.77 |

| Raptor 900 | 157,957 | 898 | 13.58 | 300 | 1,370 | 0.39 | 1.77 |

| Raptor 1100 | 334,767 | 1,100 | 16.34 | 605 | 2,173 | 0.51 | 1.77 |

| Raptor 1300 | 335,003 | 1,301 | 16.34 | 755 | 2,155 | 0.51 | 1.77 |

| Raptor 2500 | 884,249 | 2,494 | 17.72 | 1,135 | 3,860 | 0.51 | 1.77 |

Metso

Metso’s cone crusher series—GP, HP, MP, and MX—offer a range of options for various applications in mining, aggregates, and recycling. Here’s a concise overview of the technical features for each series:

GP Series

- Steep Head Angle and Crushing Cavity Design: Ensures efficient material processing and high reduction rates.

- Two-Point Supported Shaft Design: Offers mechanical reliability.

- Adjustable Stroke and Cavity Change: Allows customization for specific production requirements.

- Automation System: Monitors load and operating parameters for optimized performance.

- Versatility: Suitable for secondary, tertiary, and quaternary crushing stages.

HP Series

- Access for Liner Maintenance: Top access simplifies maintenance tasks.

- Dual-Acting Hydraulic Tramp-Release Cylinders: Provide protection against tramp iron.

- Metso IC70C™ Automation System: Enhances operation, allowing for over 10% production increase.

- Optimized Speed, Eccentricity, and Cavity Profile: Deliver higher capacity, better product quality, and suitability to a wider range of applications.

MP Series

- High Crushing Force: Offers the highest crushing force of similar-sized cone crushers for exceptional performance.

- Hydraulic Clearing System: Ensures high availability with a hydraulic clearing system for uncrushables.

- Ease of Maintenance: Features such as push-button disassembly make maintenance straightforward.

- High Capacity and Performance: Advanced crushing dynamics lead to more work per cycle, increasing capacity.

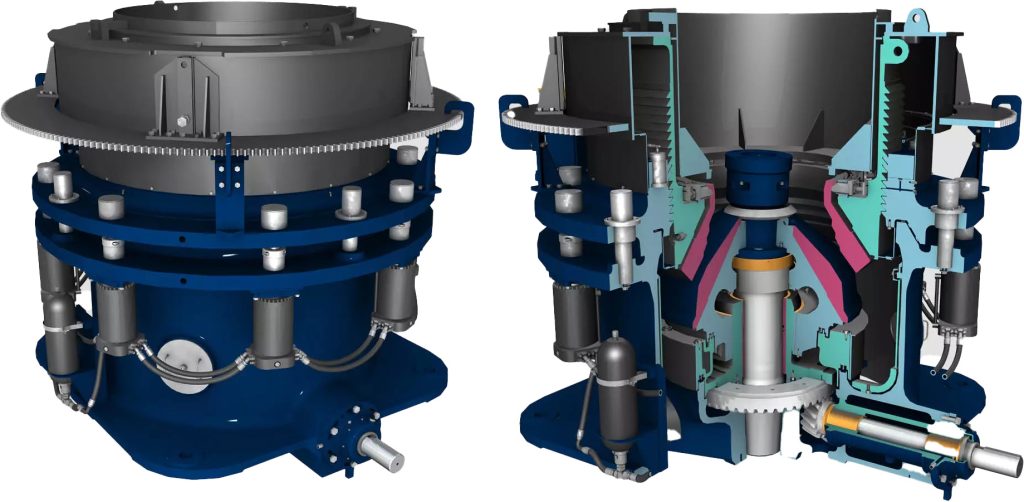

MX Series

- Multi-Action Technology: Combines the piston and rotating bowl into a single crusher, allowing for lower operating costs and increased uptime.

- Selective Production: The MX enables selective production of two end-product fractions with the same crusher.

- Automation and Safety: Comes with Metso’s IC crusher automation that ensures safe and reliable control of the crushing process.

Each series is designed with specific features to meet the needs of different crushing stages and offer various benefits such as high performance, ease of maintenance, and operational efficiency. The GP and HP series are well-suited for a wide range of applications in secondary, tertiary, and quaternary stages. The MP series is recognized for its high capacity and crushing force, making it ideal for demanding mining operations. The MX series introduces innovative technology for dynamic adjustment of the crusher operation, optimizing efficiency and enhancing safety.

Sources

https://www.metso.com/portfolio/nordberg-gp-series/

https://www.metso.com/portfolio/nordberg-hp-series/

https://www.metso.com/portfolio/nordberg-mp-series/

https://www.metso.com/globalassets/portfolio/brochure-nordberg-gp-series-4675-11-22-en-agg.pdf

https://www.metso.com/globalassets/product-pages/crushers/stationary-crushers/cone-crushers/nordberg-hp-series/brochure-nordberg-hp-series-4236-10-22-en-agg.pdf

https://www.metso.com/portfolio/nordberg-mp-series/nordberg-mp1000/

https://www.metso.com/portfolio/nordberg-gp-series/nordberg-gp500s/

https://www.metso.com/portfolio/nordberg-hp-series/nordberg-hp100/

https://www.metso.com/portfolio/nordberg-mp-series/nordberg-mp1250/

https://www.metso.com/portfolio/nordberg-gp-series/nordberg-gp300s/

https://www.metso.com/portfolio/nordberg-hp-series/nordberg-hp400/

Metso Table

Metric

| Model | Weight (kg) | Power (kWh) | Max Feed (mm) | Min Capacity (mtph) | Max Capacity (mtph) | Min CSS (mm) | Max CSS (mm) |

|---|---|---|---|---|---|---|---|

| GP100 | 6,200 | 90 | 135 | 35 | 105 | 6 | 20 |

| GP100S | 7,700 | 90 | 236 | 80 | 250 | 20 | 45 |

| GP220 | 11,100 | 220 | 204 | 70 | 310 | 8 | 35 |

| GP300S | 17,100 | 250 | 320 | 180 | 480 | 25 | 50 |

| GP330 | 16,600 | 315 | 215 | 105 | 420 | 8 | 35 |

| GP500S | 34,300 | 355 | 392 | 250 | 860 | 35 | 65 |

| GP550 | 28,700 | 400 | 235 | 160 | 575 | 15 | 45 |

| HP100 | 6,470 | 90 | 150 | – | 155 | 6 | 17 |

| HP200 | 12,160 | 132 | 185 | – | 250 | 6 | 19 |

| HP3 | 16,100 | 250 | 220 | – | 388 | 8 | 25 |

| HP300 | 18,100 | 220 | 241 | – | 440 | 6 | 25 |

| HP4 | 24,200 | 315 | 252 | – | 555 | 8 | 28 |

| HP400 | 25,600 | 315 | 304 | – | 630 | 6 | 30 |

| HP5 | 29,000 | 370 | 317 | – | 600 | 6 | 30 |

| HP500 | 37,000 | 355 | 351 | – | 790 | 6 | 30 |

| HP6 | 44,550 | 500 | 331 | – | 790 | 9 | 30 |

| HP900 | 77,960 | 700 | 356 | – | 2,000 | 9 | 32 |

| MP1000 | 153,124 | – | – | 615 | 2,420 | 13 | 50 |

| MP1250 | 153,985 | – | – | 590 | 3,025 | 10 | 50 |

| MP2500 | 450,000 | – | – | 1,560 | 7,166 | 19 | 63 |

| MP800 | 120,570 | – | – | 495 | 1,935 | 13 | 50 |

| MX3 | 16,600 | 220 | 232 | 300 | 420 | – | – |

| MX4 | 21,200 | 315 | 257 | 400 | 600 | – | – |

Imperial

| Model | Weight (lbs) | Power (hp) | Max Feed (in) | Min Capacity (stph) | Max Capacity (stph) | Min CSS (in) | Max CSS (in) |

|---|---|---|---|---|---|---|---|

| GP100 | 13,669 | 121 | 5.31 | 39 | 116 | 0.24 | 0.79 |

| GP100S | 16,976 | 121 | 9.29 | 88 | 276 | 0.79 | 1.77 |

| GP220 | 24,471 | 295 | 8.03 | 77 | 342 | 0.31 | 1.38 |

| GP300S | 37,699 | 335 | 12.60 | 198 | 529 | 0.98 | 1.97 |

| GP330 | 36,597 | 422 | 8.46 | 116 | 463 | 0.31 | 1.38 |

| GP500S | 75,618 | 476 | 15.43 | 276 | 948 | 1.38 | 2.56 |

| GP550 | 63,273 | 536 | 9.25 | 176 | 634 | 0.59 | 1.77 |

| HP100 | 14,264 | 121 | 5.91 | – | 171 | 0.24 | 0.67 |

| HP200 | 26,808 | 177 | 7.28 | – | 276 | 0.24 | 0.75 |

| HP3 | 35,494 | 335 | 8.66 | – | 428 | 0.31 | 0.98 |

| HP300 | 39,904 | 295 | 9.49 | – | 485 | 0.24 | 0.98 |

| HP4 | 53,352 | 422 | 9.92 | – | 612 | 0.31 | 1.10 |

| HP400 | 56,438 | 422 | 11.97 | – | 694 | 0.24 | 1.18 |

| HP5 | 63,934 | 496 | 12.48 | – | 661 | 0.24 | 1.18 |

| HP500 | 81,571 | 476 | 13.82 | – | 871 | 0.24 | 1.18 |

| HP6 | 98,216 | 671 | 13.03 | – | 871 | 0.35 | 1.18 |

| HP900 | 171,872 | 939 | 14.02 | – | 2,205 | 0.35 | 1.26 |

| MP1000 | 337,580 | – | – | 678 | 2,668 | 0.51 | 1.97 |

| MP1250 | 339,478 | – | – | 650 | 3,334 | 0.39 | 1.97 |

| MP2500 | 992,079 | – | – | 1,720 | 7,899 | 0.75 | 2.48 |

| MP800 | 265,811 | – | – | 546 | 2,133 | 0.51 | 1.97 |

| MX3 | 36,597 | 295 | 9.13 | 331 | 463 | – | – |

| MX4 | 46,738 | 422 | 10.12 | 441 | 661 | – | – |

Sandvik

Sandvik’s CH and CS series cone crushers are engineered for a wide range of applications, including secondary, tertiary, quaternary, and pebble-crushing applications. These crushers combine high performance with low total cost, making them suitable for quarrying and mining segments. Here’s a summary of their technical features:

CH Series

- Hydroset™ System: Provides safety and setting-adjustment functions, enhancing operational safety and flexibility.

- ASRi™ Automation: Coupled with the Hydroset™ system, it automatically adapts the crusher to varying feed conditions, ensuring maximum performance.

- Robust Design: The mainframe is built as a unibody without moving parts, optimizing strength and reducing maintenance.

- Adjustable Eccentric Throw: Allows customization of capacity to the process, harmonizing crushing stages.

- Constant Liner Profile: Maintains feed opening and performance throughout the liner’s service life, optimizing productivity.

- Wide Range of Crushing Chambers: Offers flexibility for all types of applications, from extra coarse to extremely fine crushing chambers.

- PLC Controlled Electric Dump Valve: Provides tramp iron protection, reducing mechanical stress on the crusher and improving reliability.

CS Series

- Adjustable Eccentric Throw and Constant Intake Opening: Ensures the crusher is suitable for high-capacity secondary crushing applications.

- Hydraulically Supported Main Shaft: Supported at both ends for increased durability.

- Hydroset™ System and ASRi™ Automation: Provide safety, setting-adjustment functions, and real-time performance management.

- Unibody Mainframe: Ensures optimal strength and less maintenance.

- Lifting from Above: Minimizes risks and allows for safer maintenance.

- Reliability and Protection Package: Includes on-site periodic inspections, preventative maintenance recommendations, and a comprehensive warranty.

Both the CH and CS series are designed with a focus on safety, ease of maintenance, and operational efficiency. The CH series is particularly noted for its advanced technology and flexibility to meet specific requirements of mines or large-sized quarries, while the CS series is recognized for its high capacity and robust design, making it suitable for secondary crushing applications. Sandvik’s cone crushers are equipped with the latest innovations, such as the Hydroset™ system and ASRi™ automation, to ensure optimized performance and control of the crushing process.

Sources

https://www.rockprocessing.sandvik/en/products/stationary-crushers/

https://www.rocktechnology.sandvik/globalassets/products/stationary-crushers-and-screens/pdf/ch860-ch865-specification-sheet-english.pdf

https://www.rocktechnology.sandvik/globalassets/products/stationary-crushers-and-screens/pdf/cs550-specification-sheet-english.pdf

https://www.rocktechnology.sandvik/globalassets/products/stationary-crushers-and-screens/pdf/ch870i-technical-specification-english.pdf

Sandvik Table

Metric

| Model | Weight (kg) | Power (kWh) | Max Feed (mm) | Min Capacity (mtph) | Max Capacity (mtph) | Min CSS (mm) | Max CSS (mm) |

|---|---|---|---|---|---|---|---|

| CH420 | 6,130 | 90 | 155 | 23 | 135 | 4 | 35 |

| CH430 | 10,516 | 132 | 214 | 26 | 215 | 4 | 41 |

| CH440 | 16,617 | 220 | 250 | 58 | 336 | 8 | 48 |

| CH660 | 29,335 | 315 | 321 | 116 | 646 | 10 | 51 |

| CH830i | 12,734 | 250 | 211 | 61 | 283 | 5 | 41 |

| CH840i | 20,278 | 330 | 250 | 212 | 659 | 22 | 70 |

| CH860i | 39,710 | 500 | 315 | 250 | 910 | 13 | 51 |

| CH865i | 38,930 | 500 | 123 | 155 | 517 | 10 | 44 |

| CH870i | 58,293 | 600 | 350 | 208 | 1,370 | 10 | 70 |

| CH890i | 84,891 | 750 | 428 | 275 | 1,837 | 13 | 70 |

| CH895i | 84,343 | 750 | 127 | 258 | 1,077 | 10 | 70 |

| CS420 | 7,188 | 90 | 267 | 70 | 172 | 13 | 35 |

| CS430 | 13,098 | 132 | 400 | 99 | 298 | 24 | 54 |

| CS440 | 21,637 | 220 | 500 | 191 | 510 | 25 | 57 |

| CS660 | 40,254 | 315 | 622 | 314 | 908 | 29 | 83 |

| CS840i | 25,794 | 330 | 431 | 212 | 659 | 22 | 70 |

Imperial

| Model | Weight (lbs) | Power (hp) | Max Feed (in) | Min Capacity (stph) | Max Capacity (stph) | Min CSS (in) | Max CSS (in) |

|---|---|---|---|---|---|---|---|

| CH420 | 13,514 | 121 | 6.10 | 25 | 149 | 0.16 | 1.38 |

| CH430 | 23,184 | 177 | 8.43 | 29 | 237 | 0.16 | 1.61 |

| CH440 | 36,634 | 295 | 9.84 | 64 | 370 | 0.31 | 1.89 |

| CH660 | 64,673 | 422 | 12.64 | 128 | 712 | 0.39 | 2.01 |

| CH830i | 28,074 | 335 | 8.31 | 67 | 312 | 0.20 | 1.61 |

| CH840i | 44,705 | 443 | 9.84 | 234 | 726 | 0.87 | 2.76 |

| CH860i | 87,545 | 671 | 12.40 | 276 | 1,003 | 0.51 | 2.01 |

| CH865i | 85,826 | 671 | 4.84 | 171 | 570 | 0.39 | 1.73 |

| CH870i | 128,514 | 805 | 13.78 | 229 | 1,510 | 0.39 | 2.76 |

| CH890i | 187,152 | 1,006 | 16.85 | 303 | 2,025 | 0.51 | 2.76 |

| CH895i | 185,944 | 1,006 | 5.00 | 284 | 1,187 | 0.39 | 2.76 |

| CS420 | 15,847 | 121 | 10.51 | 77 | 190 | 0.51 | 1.38 |

| CS430 | 28,876 | 177 | 15.75 | 109 | 328 | 0.94 | 2.13 |

| CS440 | 47,701 | 295 | 19.69 | 211 | 562 | 0.98 | 2.24 |

| CS660 | 88,745 | 422 | 24.49 | 346 | 1,001 | 1.14 | 3.27 |

| CS840i | 56,866 | 443 | 16.97 | 234 | 726 | 0.87 | 2.76 |

Superior Industries

Superior Industries offers a range of cone crushers, each with distinct features tailored to various crushing needs. Here’s an overview of the technical features for the Dakota, Endeavor, and Patriot cone crushers:

Dakota™ Cone Crusher

- Roller Bearing Design: Offers efficient use of horsepower per ton of crushed rock, which is typically more efficient than other bearing types.

- Applications: Suitable for ore/hard rock mining, quarried stone, river gravel, recycled concrete, fractured gravel, and more.

Endeavor™ Cone Crusher

- Spider Bushing Cone: Provides efficient and reliable crushing performance.

- Design: In addition to traditional bushing and bearing models, Superior also manufactures this spider bushing cone crusher.

Patriot® Cone Crusher

- High-Performance Bushing Cone: Known for its durability and productivity, setting industry standards.

- Advanced Tramp Relief System: Features an inverted cylinder design to protect hydraulic seals from contamination, reducing maintenance.

- Counterclockwise Rotation: Helps prevent major damage by allowing the crusher to open up if there’s a loss in clamping pressure.

- Enclosed Counterweight Assembly: Protects the counterweight from material wear with an easy-to-remove bolt-on guard.

- Vantage® Automation: In-house designed automation system for precise control, warning of harmful conditions, and improving efficiencies.

- Robust Design: Includes features like a steel threaded bowl, one-piece cast mainframe, and a tramp relief system with fewer accumulators for simplified maintenance.

- Proven Performance: Engineered to perform at higher speeds with less noise and vibration.

The Dakota is recognized for its roller bearing design, which is efficient for various crushing applications. The Endeavor introduces a spider bushing cone for reliable performance. The Patriot series is noted for its robust design, advanced tramp relief system, and automation capabilities, making it a durable and productive choice for secondary or tertiary applications in mining and aggregate operations.

Sources

https://superior-ind.com/products/crushing-equipment/dakota-cone-crusher/

https://superior-ind.com/products/crushing-equipment/endeavor-cone-crusher/

https://superior-ind.com/products/crushing-equipment/patriot-cone-crusher/

Superior Industries Table

Metric

| Model | Weight (kg) | Power (kWh) | Max Feed (mm) | Min Capacity (mtph) | Max Capacity (mtph) | Min CSS (mm) | Max CSS (mm) |

|---|---|---|---|---|---|---|---|

| Dakota D350 | 20,870 | 260 | 305 | 155 | 415 | 13 | 51 |

| Endeavor SS300 | 19,980 | 225 | 450 | – | – | 24 | 54 |

| Endeavor ST300 | 15,870 | 225 | 210 | – | – | 8 | 44 |

| Patriot 200 | 8,838 | 150 | 236 | 91 | 308 | 10 | 50 |

| Patriot 300 | 16,029 | 225 | 270 | 163 | 490 | 10 | 50 |

| Patriot 400 | 24,130 | 300 | 310 | 181 | 581 | 10 | 50 |

| Patriot 500 | 33,566 | 375 | 343 | 227 | 726 | 10 | 50 |

| Patriot 600 | 51,113 | 450 | 356 | 272 | 744 | 10 | 50 |

| Patriot 800 | 92,000 | 600 | 360 | 470 | 1,450 | 10 | 50 |

Imperial

| Model | Weight (lbs) | Power (hp) | Max Feed (in) | Min Capacity (stph) | Max Capacity (stph) | Min CSS (in) | Max CSS (in) |

|---|---|---|---|---|---|---|---|

| Dakota D350 | 46,010 | 349 | 12.01 | 171 | 457 | 0.51 | 2.01 |

| Endeavor SS300 | 44,048 | 302 | 17.72 | – | – | 0.94 | 2.13 |

| Endeavor ST300 | 34,987 | 302 | 8.27 | – | – | 0.31 | 1.73 |

| Patriot 200 | 19,484 | 201 | 9.29 | 100 | 340 | 0.39 | 1.97 |

| Patriot 300 | 35,338 | 302 | 10.63 | 180 | 540 | 0.39 | 1.97 |

| Patriot 400 | 53,197 | 402 | 12.20 | 200 | 640 | 0.39 | 1.97 |

| Patriot 500 | 74,000 | 503 | 13.50 | 250 | 800 | 0.39 | 1.97 |

| Patriot 600 | 112,685 | 603 | 14.02 | 300 | 820 | 0.39 | 1.97 |

| Patriot 800 | 202,825 | 805 | 14.17 | 518 | 1,598 | 0.39 | 1.97 |

Terex

Terex offers a comprehensive range of cone crushers through its MVP, TC, and TG series, each designed to meet specific needs in the crushing industry. Here’s a detailed look at the technical features of these series:

MVP Series

The MVP series cone crushers are known for their ability to handle tough crushing operations with advanced engineering and high endurance construction. Key features include:

- All-Cast Construction: Enhanced durability with new upper and lower frame castings; rugged, field-proven cone head and bowl nut castings.

- ElJay® Roller Bearing Design: Provides efficient use of horsepower, leading to better crushing efficiency.

- Hydropneumatic Tramp Iron Relief System: Revolutionized the industry by providing better protection and reducing downtime.

- High Throughput Capacities: Capable of processing up to 810 tons per hour, depending on the model.

- Versatility: Offers a range of models for stationary or portable configurations, suitable for handling sand, gravel, shot rock, and recycled materials.

TC Series

The TC series is designed for robust performance and high quality aggregate production. Features include:

- Robust Construction: Designed for the most arduous applications with fully automatic controls.

- Low Profile: Important where headroom is restricted, making it ideally suited for mobile plant applications.

- Advanced Hydraulics: Features accessible external hydraulics, hydraulic setting adjustment, and automatic hydraulic overload protection and reset.

- Simple Wear Part Change: Designed for fast changeover to keep downtime to a minimum.

- Advanced Bearing Arrangement: High capacity taper and cylindrical roller bearings ensure long, trouble-free service.

TG Series

The TG series, including the TGS variant, offers exceptional versatility, superior productivity, and consistent performance. The series is characterized by:

- Spider Bearing Design: Provides efficient and reliable crushing performance across the TG series.

- Advanced Automation Control System: Standard on all TG Series Cones, this system improves performance and safety by monitoring operational parameters and making necessary adjustments.

- Large Feed Opening: The TGS series, in particular, can accept a significantly larger feed size compared to other cones in the same power rating, thanks to its steep angled head design.

- Versatility in Application: From coarse secondary crushing to fine quaternary, the TG series can be easily adapted to all application requirements at minimal cost.

Each of these series from Terex is designed with specific operational needs in mind, from the rugged and reliable MVP series, through the robust and versatile TC series, to the innovative and adaptable TG series, ensuring a wide range of crushing solutions for the industry.

Sources

https://www.terex.com/docs/librariesprovider8/brochures/tmps_static_brochure_mvpx_series_a4.pdf?sfvrsn=2f7751cc_11

https://www.terex.com/docs/librariesprovider8/spec-sheets/static/tc-product-specification.pdf?sfvrsn=81e58077_34

https://www.terex.com/docs/librariesprovider8/brochures/cedarapids_tg_series_brochurece11022020-generic-controls-letter.pdf?sfvrsn=4ae63095_59

https://www.terex.com/docs/librariesprovider8/spec-sheets/static/tc1150-specification-sheet.pdf?sfvrsn=d99eab75_65

https://www.terex.com/mps/en/tg-cones

https://www.terex.com/mps/en/product/static-cone-crusher/tc1000

https://www.terex.com/mps/en/product/static-cone-crusher/tg320

https://www.terex.com/mps/en-au/products/static/static-cone-crusher/static-cone-crusher/mvp450x

https://www.terex.com/mps/en-in/product/static-cone-crusher/tc1300

Terex Table

Metric

| Model | Weight (kg) | Power (kWh) | Max Feed (mm) | Min Capacity (mtph) | Max Capacity (mtph) | Min CSS (mm) | Max CSS (mm) |

|---|---|---|---|---|---|---|---|

| MVP380X | 20,800 | 225 | 283 | 155 | 507 | 10 | 51 |

| MVP450X | 23,800 | 300 | 329 | 182 | 585 | 10 | 51 |

| MVP550X | 30,800 | 375 | 346 | 228 | 737 | 10 | 51 |

| TC1000 | 10,000 | 170 | 195 | 70 | 200 | 16 | 36 |

| TC1150 | 14,000 | 225 | 220 | 150 | 290 | 16 | 40 |

| TG120 | 5,500 | 90 | 125 | – | 130 | 6 | 29 |

| TG220 | 9,500 | 160 | 165 | – | 215 | 6 | 32 |

| TG320 | 15,000 | 250 | 190 | – | 410 | 8 | 38 |

| TG320 | 19,500 | 250 | 330 | – | 601 | 29 | 48 |

| TG420 | 25,200 | 315 | 240 | – | 680 | 13 | 44 |

| TG820 | 50,000 | 600 | 320 | – | 1,550 | 13 | 64 |

| TG1020 | 77,000 | 750 | 355 | – | 2,300 | 13 | 70 |

| TGS120 | 6,850 | 90 | 190 | – | 143 | 9 | 35 |

| TGS220 | 12,100 | 160 | 275 | – | 344 | 19 | 35 |

| TGS420 | 36,500 | 315 | 385 | – | 1,050 | 38 | 70 |

Imperial

| Model | Weight (lbs) | Power (hp) | Max Feed (in) | Min Capacity (stph) | Max Capacity (stph) | Min CSS (in) | Max CSS (in) |

|---|---|---|---|---|---|---|---|

| MVP380X | 45,856 | 302 | 11.14 | 171 | 559 | 0.39 | 2.01 |

| MVP450X | 52,470 | 402 | 12.95 | 201 | 645 | 0.39 | 2.01 |

| MVP550X | 67,902 | 503 | 13.62 | 251 | 812 | 0.39 | 2.01 |

| TC1000 | 22,046 | 228 | 7.68 | 77 | 220 | 0.63 | 1.42 |

| TC1150 | 30,865 | 302 | 8.66 | 165 | 320 | 0.63 | 1.57 |

| TG120 | 12,125 | 121 | 4.92 | – | 143 | 0.24 | 1.14 |

| TG220 | 20,944 | 215 | 6.50 | – | 237 | 0.24 | 1.26 |

| TG320 | 33,069 | 335 | 7.48 | – | 452 | 0.31 | 1.50 |

| TG320 | 42,990 | 335 | 12.99 | – | 662 | 1.14 | 1.89 |

| TG420 | 55,556 | 422 | 9.45 | – | 750 | 0.51 | 1.73 |

| TG820 | 110,231 | 805 | 12.60 | – | 1,709 | 0.51 | 2.52 |

| TG1020 | 169,756 | 1,006 | 13.98 | – | 2,535 | 0.51 | 2.76 |

| TGS120 | 15,102 | 121 | 7.48 | – | 158 | 0.35 | 1.38 |

| TGS220 | 26,676 | 215 | 10.83 | – | 379 | 0.75 | 1.38 |

| TGS420 | 80,469 | 422 | 15.16 | – | 1,157 | 1.50 | 2.76 |

Weir Minerals

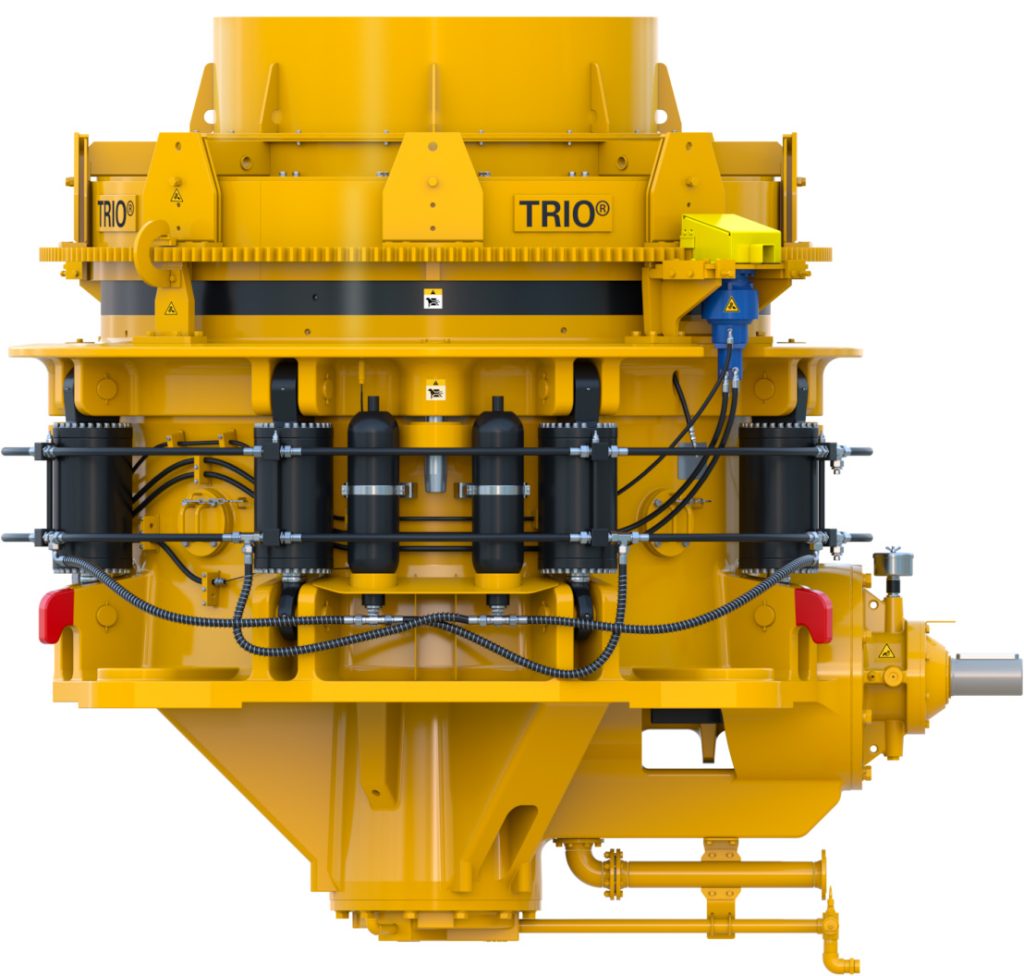

Weir Minerals offers a comprehensive range of cone crushers through its Trio® TC, TP, and the newly introduced TC84XR series, each designed to meet specific needs in the crushing industry with a focus on safety, functionality, and reliability. Here’s a detailed look at the technical features of these series:

Trio® TC Series

The TC Series is designed for robust performance in heavy-duty secondary and tertiary crushing applications. It is known for its tough, reliable, and simple to operate and maintain design. Key features include:

- Live-Shaft Design: Proven to perform in heavy-duty applications, enhancing the crusher’s durability and reliability.

- Advanced Hydraulics: Equipped with modern hydraulic features that allow safe and easy adjustment of crusher settings.

- High Crushing Force: Delivers increased horsepower and moderate increases in crushing speed.

- Robust Construction: Ensures the crusher is durable and capable of handling demanding crushing operations.

Trio® TP Series

The TP Series is designed to deliver high performance and maximum reliability in secondary, tertiary, or quaternary crushing applications. Its features include:

- Steep Crushing Chamber Angle: A large crushing stroke and optimized speed deliver a finer product through increased inter-particle comminution.

- High Pivot Point: Enhances the series’ crushing action for better end product shape and high production of salable material.

- Advanced Automation: Comes with automation that monitors and controls the crusher operation, enhancing safety and performance.

Trio® TC84XR Series

The TC84XR is the latest addition to the Trio® range, introducing several new design elements to improve safety, functionality, and reliability. Notable features include:

- Live-Shaft Design: Maintains the proven performance of live-shaft crushers while incorporating the latest technology for enhanced functionality.

- Higher Crushing Capacity: Features a larger motor compared to equivalent sized crushers, offering higher power capability and potential crushing force.

- Robust and Powerful: Engineered to perform in the most extreme applications, delivering high crushing force and horsepower in primary, crushed ore, and quarry rock applications.

- Variable Feed and Pebble Crushing: Capable of handling variable feed and effectively crushing pebbles, partly due to its large motor.

- Advanced Technology Upgrades: Includes improvements in safety, functionality, and reliability, making it a technologically advanced crusher.

The Trio® TC, TP, and TC84XR series from Weir Minerals are designed to meet the diverse needs of the crushing industry, offering a range of solutions that prioritize safety, efficiency, and reliability. The introduction of the TC84XR series highlights Weir Minerals’ commitment to innovation and its focus on providing crushers that are robust, powerful, and equipped with the latest technology to ensure optimal performance in demanding applications.

Sources

https://www.global.weir/newsroom/global-news/weir-minerals-new-trio-tc84xr-live-shaft-cone-crusher-improves-safety-functionality-and-reliability/

https://www.global.weir/globalassets/resources/product-pdfs/trio/trio-tp-series-combined-spec-sheets.pdf

https://www.global.weir/product-catalogue/crushing-equipment/trio-tc-series-cone-crushers/

Weir Minerals Table

Metric

| Model | Weight (kg) | Power (kWh) | Max Feed (mm) | Min Capacity (mtph) | Max Capacity (mtph) | Min CSS (mm) | Max CSS (mm) |

|---|---|---|---|---|---|---|---|

| TC36 | 12,000 | 90 | 184 | 63 | 186 | 6 | 38 |

| TC51 | 22,500 | 200 | 271 | 90 | 426 | 6 | 51 |

| TC66 | 43,500 | 250 | 282 | 154 | 562 | 6 | 51 |

| TC84XR | 78,000 | 450 | 383 | 318 | 1,590 | 6 | 64 |

| TP260 | 12,000 | 185 | 244 | 72 | 259 | 6 | 38 |

| TP350 | 18,500 | 250 | 245 | 113 | 490 | 6 | 45 |

| TP450 | 25,000 | 315 | 305 | 146 | 673 | 8 | 51 |

| TP600 | 35,000 | 450 | 296 | 194 | 832 | 8 | 51 |

| TP900 | 76,000 | 630 | 320 | 279 | 1,166 | 8 | 57 |

Imperial

| Model | Weight (lbs) | Power (hp) | Max Feed (in) | Min Capacity (stph) | Max Capacity (stph) | Min CSS (in) | Max CSS (in) |

|---|---|---|---|---|---|---|---|

| TC36 | 26,455 | 121 | 7.24 | 69 | 205 | 0.24 | 1.50 |

| TC51 | 49,604 | 268 | 10.67 | 99 | 470 | 0.24 | 2.01 |

| TC66 | 95,901 | 335 | 11.10 | 170 | 619 | 0.24 | 2.01 |

| TC84XR | 171,960 | 603 | 15.08 | 351 | 1,753 | 0.24 | 2.52 |

| TP260 | 26,455 | 248 | 9.61 | 79 | 285 | 0.24 | 1.50 |

| TP350 | 40,785 | 335 | 9.65 | 125 | 540 | 0.24 | 1.77 |

| TP450 | 55,116 | 422 | 12.01 | 161 | 742 | 0.31 | 2.01 |

| TP600 | 77,162 | 603 | 11.65 | 214 | 917 | 0.31 | 2.01 |

| TP900 | 167,551 | 845 | 12.60 | 308 | 1,285 | 0.31 | 2.24 |

Power vs. Max Capacity by Company

Click on a company name to hide them in the chart